Welcome to an in-depth review of WoodCuttingBoards.com, a leading online retailer specializing in premium, custom, and laser-engraved wooden cutting boards. In a world increasingly focused on quality, durability, and personalized touches, WoodCuttingBoards.com stands out as a purveyor of handcrafted kitchen essentials that blend functionality with aesthetic appeal. This article will delve into their exquisite product range, the unparalleled craftsmanship, the art of customization, and essential care tips to ensure your investment lasts a lifetime.

Discover the Craftsmanship: An In-Depth WoodCuttingBoards.com Review

Every kitchen, from the professional chef’s station to the home cook’s sanctuary, deserves reliable and beautiful tools. Cutting boards are fundamental to food preparation, serving as the unsung heroes of culinary endeavors. While various materials exist, wood remains the top choice for its durability, knife-friendliness, and timeless elegance. WoodCuttingBoards.com elevates this essential tool into a work of art, offering products that are not just utilitarian but also conversation starters.

In our own Steamy Kitchen, we utilize a diverse set of cutting boards to tackle every culinary task. For raw meats and fish, we opt for an antimicrobial poly cutting board, such as those from Neoflam. These are typically large, lightweight, and equipped with silicone grips to prevent slipping, making them ideal for quick sanitization in the dishwasher or with a bleach solution after handling proteins.

However, for the majority of our daily preparations – fruits, vegetables, cheeses, cooked meats, and even rolling out dough – our preference invariably leans towards a substantial wooden cutting board. We often rely on a custom-made walnut board, generously sized at approximately 30 inches square, which permanently graces our countertop. Its expansive surface allows us to prepare multiple ingredients simultaneously without the need for constant washing or transferring, significantly streamlining our cooking process. The natural warmth and robust feel of wood make every chopping experience a pleasure.

Our recent experience with walnut cutting boards from WoodCuttingBoards.com left us thoroughly impressed. The moment you unbox one of their boards, the superior quality is palpable. What truly sets them apart is their unwavering commitment to sourcing and craftsmanship. All their products are proudly made in North America, catering to customers across both Canada and the USA. This dedication to local manufacturing ensures stringent quality control and supports ethical production practices.

They craft their boards from 100% high-quality, sustainably sourced hardwoods, including rich maple, exquisite walnut, and vibrant cherry. Each wood type offers unique characteristics: maple is known for its light color and exceptional durability, walnut boasts deep, luxurious tones and a beautiful grain, while cherry presents a warm, reddish hue that deepens with age. This selection allows customers to choose a board that not only performs impeccably but also complements their kitchen aesthetic perfectly.

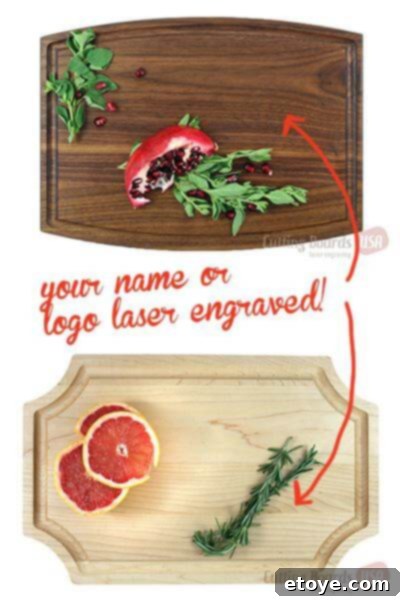

Personalization Perfected: Laser Engraving Services

Beyond their exceptional standard products, WoodCuttingBoards.com offers a highly sought-after custom laser engraving service, turning an ordinary cutting board into a cherished keepsake or a powerful branding tool. We had the pleasure of having our Steamy Kitchen logo meticulously engraved onto both sides of our new board, and the results were nothing short of spectacular.

The customization process is remarkably user-friendly. Simply upload a JPG file of your desired logo or design to their online ordering page, and their team will collaborate with you to ensure the perfect size and precise positioning of the laser engraving. The precision of their laser technology is truly outstanding; even the smallest, most intricate details, like the tiny dots representing steam in our logo, were reproduced with absolute perfection. This level of detail makes their custom boards ideal for personalized gifts, wedding presents, corporate branding, or simply adding a unique touch to your own kitchen.

Understanding Wood Grains: End Grain vs. Edge Grain Cutting Boards

When selecting a wooden cutting board, one of the most critical decisions involves the type of grain construction: edge grain or end grain. Each offers distinct advantages and visual characteristics, catering to different preferences and uses.

Edge Grain Cutting Boards

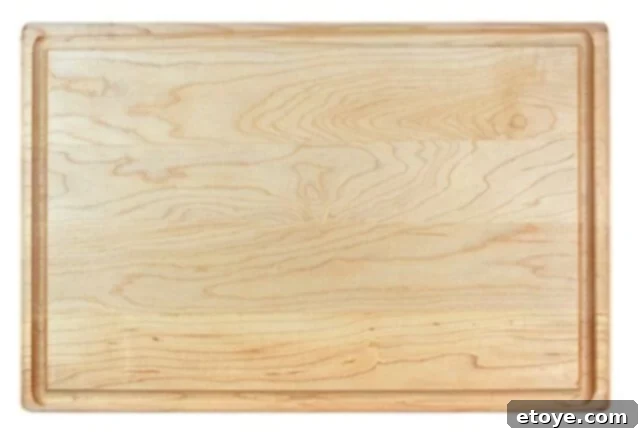

The most commonly encountered wooden cutting boards are constructed using the edge grain method. In this technique, individual strips of wood are laid side by side, with their long edges fused together to form a solid surface. This construction method beautifully showcases the natural patterns and flowing lines of the wood’s grain, resulting in an aesthetically pleasing board that often highlights the wood’s unique character.

Edge grain boards are generally more affordable to produce, making them an excellent entry point into the world of quality wooden cutting boards. They are sturdy and reliable, perfect for general kitchen tasks. However, due to the orientation of the wood fibers, cutting marks and knife scores tend to be more visible on the surface over time. While this doesn’t diminish their functionality, it’s a factor to consider for those seeking a pristine appearance for longer periods.

End Grain Cutting Boards: The Professional’s Choice

For the discerning chef or serious home cook, end grain cutting boards are often the preferred choice, and for good reason. Their construction involves a more intricate process: long strips of wood are first fused together, and then a board is cut lengthwise, revealing the ends of the wood grains. This unique orientation positions the wood fibers vertically, much like a bundle of tiny straws.

The primary benefit of end grain construction lies in its remarkable “self-healing” properties and superior knife protection. When your sharp knife blade makes contact with an end grain board, it slides between these vertically oriented fibers, rather than cutting directly across them. This action is akin to the knife being “cushioned” by the fibrous ends of the wood. Consequently, this keeps your knives sharper for significantly longer periods, reducing the frequency of sharpening. Furthermore, fewer visible scratches and cut marks will appear on the board’s surface, preserving its beauty and longevity.

While end grain boards offer unparalleled performance for cutting, they do require a bit more diligence in care. Because the exposed end fibers can absorb water and liquids much like a sponge, it is absolutely crucial to dry the cutting board immediately and thoroughly after hand-washing. Prolonged exposure to moisture can lead to warping, cracking, or discoloration.

Generally, end grain cutting boards are thicker, heavier, and consequently, more expensive than their edge grain counterparts. This added cost reflects the more complex manufacturing process and the superior benefits they offer. For anyone serious about chopping, dicing, and protecting their valuable knife collection, we wholeheartedly recommend the end grain option. You’ll truly appreciate the softer feel under your knife – that subtle “give” from the wood fibers makes a noticeable difference in comfort and performance.

Mastering the Art of Cutting Board Care and Maintenance

Investing in a high-quality wooden cutting board from WoodCuttingBoards.com is just the first step; proper care is paramount to preserving its beauty, functionality, and longevity. With a few simple habits, you can ensure your board remains a prized kitchen tool for many years to come.

Immediate Drying is Key

The golden rule for wooden cutting boards is to never let them soak in water or run them through a dishwasher. Dishwashers subject wood to extreme temperatures and prolonged submersion, which will inevitably lead to warping, cracking, and a dull, dry appearance. After hand-washing your board with mild soap and warm water, it is imperative to dry it immediately with a clean towel. To promote even drying and prevent moisture from getting trapped underneath, it’s best to stand the board on its edge or use a drying rack rather than laying it flat on a counter.

Regular Conditioning and Oiling

Wood is a natural material that needs moisture to remain supple and prevent drying out. Over time, repeated washing will strip the wood of its natural oils, making it susceptible to cracking, splitting, and warping. To combat this, regular conditioning is essential, ideally once a month or whenever the board begins to look dry. WoodCuttingBoards.com offers a high-quality beeswax conditioner for $14.99, specifically formulated for their boards.

To condition, simply apply a generous amount of food-safe conditioner or mineral oil to both sides of the board. Use your hands or a soft cloth to rub it in thoroughly, ensuring complete coverage. Allow the oil to penetrate the wood for several hours, or even overnight, before wiping off any excess with a clean, dry cloth. This process not only revitalizes the wood but also creates a protective barrier that helps repel water and food stains. There’s no need to wash the board after conditioning; it’s ready for use.

Protecting the Underside and Proper Storage

Another crucial tip for preventing warping is to ensure proper air circulation around your board, especially its underside. We always recommend placing something underneath the cutting board during use, such as a clean towel, a silicone mat, or even a small piece of non-slip drawer liner material. This not only helps prevent the board from slipping dangerously during cutting but also creates a barrier, keeping the wooden surface elevated off the countertop. This elevation prevents trapped moisture from accumulating underneath, which can lead to warping and ruin the board over time. When not in use, store your board upright or in a dry, well-ventilated area, away from direct heat sources like ovens or radiators.

Our Resounding Recommendation: WoodCuttingBoards.com

After thorough evaluation and extensive use, we unequivocally recommend WoodCuttingBoards.com for anyone seeking a superior wooden cutting board. The quality of their boards is truly top-notch – consistently even, free from splinters or nicks, and crafted with meticulous attention to detail. We were particularly impressed that their boards arrive pre-conditioned, ready for immediate use, a testament to their commitment to customer satisfaction.

When considering their laser engraving service, our advice is to keep the design relatively small and position it in a corner or along an edge. While the engraving is incredibly precise and adds a beautiful personalized touch, the etched areas can potentially trap food bits and bacteria if not scrubbed thoroughly during cleaning. A smaller design minimizes this concern without sacrificing the aesthetic appeal. The pride in North American craftsmanship shines through in every product, offering peace of mind regarding ethical production and quality materials.

WoodCuttingBoards.com delivers more than just cutting boards; they deliver heirloom-quality kitchen tools designed to enhance your culinary experience for years to come. Their commitment to quality, customization, and customer care makes them a standout choice in the market for premium wooden cutting boards.

WoodCuttingBoards.com Exclusive Giveaway!

To celebrate their exceptional craftsmanship and give back to our readers, WoodCuttingBoards.com is generously giving away a $100 gift certificate! This is your chance to experience the superior quality and personalized artistry of their cutting boards firsthand. Don’t miss out on this fantastic opportunity to upgrade your kitchen with a beautiful, durable, and custom-engraved wooden cutting board.