Build Your Dream Backyard Oasis: The Palace Chicken Coop Plans

Creating a functional, secure, and beautiful home for your backyard flock is a rewarding endeavor. For many, the journey begins with an inspiring vision and a set of reliable chicken coop plans. We are thrilled to share the culmination of our extensive design and build process: The Palace Chicken Coop, a stunning and highly practical structure now available through comprehensive construction drawings.

Our meticulously crafted Palace Chicken Coop Construction Drawings are now complete and ready to empower your building project. This professional 32-page PDF document provides every essential detail and precise measurement needed to replicate this magnificent chicken coop. Developed by a licensed architect, these plans ensure structural integrity and ease of assembly. The package includes a complete Bill of Materials, an updated 3D model for clear visualization, and much more. You’ll find detailed information about acquiring these professional plans at the conclusion of this article. For those who prefer to work directly from the original model that inspired this coop, a link to the SketchUp file remains available. Our trusted partners at Happy For A Living proudly make these exceptional plans accessible to aspiring coop builders.

Get Your Palace Chicken Coop Plans Today!

by Scott

The journey to building the Palace Chicken Coop began in July of last year when Jaden introduced five adorable, fluffy new friends to our family. It quickly became clear that a chicken coop was not just a possibility but a delightful necessity. Driven by a passion for hands-on projects, I eagerly embraced the challenge of designing and building their new home myself.

My initial research phase involved countless hours on platforms like Backyard Chickens, soaking up a wealth of ideas and suggestions from experienced keepers. The generosity of individuals sharing their chicken coop photos and construction journeys provided invaluable tips, creative ideas, and profound inspiration. We extend our deepest gratitude to this vibrant community; without their willingness to share their passion and hard work, our girls wouldn’t have such a splendid home. In that spirit of shared knowledge, I’ve compiled this pictorial guide to illustrate the construction of our Palace Chicken Coop. Should you have any questions about specific steps or techniques, please don’t hesitate to ask, and I’ll endeavor to provide the best possible answers.

Designing the Ultimate DIY Chicken Coop: The Palace

The Vision: Essential Design Requirements for Our Palace Chicken Coop

From the outset, we established a clear set of requirements to guide the design of our Palace Chicken Coop. These principles ensured the coop would be a sanctuary for our hens, a manageable structure for us, and a robust addition to our property. Our key considerations included:

- Aesthetic Appeal: As the coop would be a highly visible feature in our yard, it needed to be visually pleasing and integrate harmoniously with our landscape.

- Ease of Cleaning and Maintenance: Practicality was paramount. We designed for easy access, including sufficient height to stand upright inside, simplifying routine cleaning and upkeep.

- Structural Durability: Living in Florida means preparing for occasional tropical storms. The coop needed to be exceptionally sturdy to withstand challenging weather conditions.

- Deep Litter Method (DLM) Compatibility: We planned to implement the Deep Litter Method in both the coop and the attached run, necessitating appropriate design elements to support this system.

- Flood Resistance: The chosen location in our yard was prone to summer rain flooding. The design had to proactively address drainage and elevate the coop to mitigate water issues.

- Optimal Ventilation: Good airflow and ventilation were critical for the hens’ health and comfort, especially in Florida’s humid climate.

- Ample Space: The coop needed sufficient room for 5-7 hens, anticipating potential additions to our flock.

I dedicated nearly two weeks to late-night online research, meticulously gathering ideas and formulating a comprehensive plan of attack for this ambitious DIY chicken coop project. Every detail was cross-referenced and double-checked, from the precise space requirements per bird and the nuances of the Deep Litter Method to optimal nesting box dimensions, roosting bar lengths, local building codes, roofing solutions, predator-proofing strategies, waterproofing techniques, advanced drainage ideas, working with concrete, and even the safe use of explosive nailers. The internet proved to be an indispensable resource throughout this intensive planning phase.

*** Important Disclaimer ***: It is crucial to note that I am neither a licensed architect nor a structural engineer. The Palace Chicken Coop plans have not been certified to withstand extreme natural disasters such as hurricanes, earthquakes, volcanic eruptions, severe flooding, or nuclear blasts. My professional background is in computer engineering, with training from West Point Military Academy, which instilled in me an obsessively detailed and thorough approach. I am proud to report that our chicken coop successfully passed all local inspections. Rest assured, no chickens were harmed during the construction of this coop, and all testing was conducted under strictly controlled conditions. Please consult local building regulations and consider professional advice for specific environmental conditions.

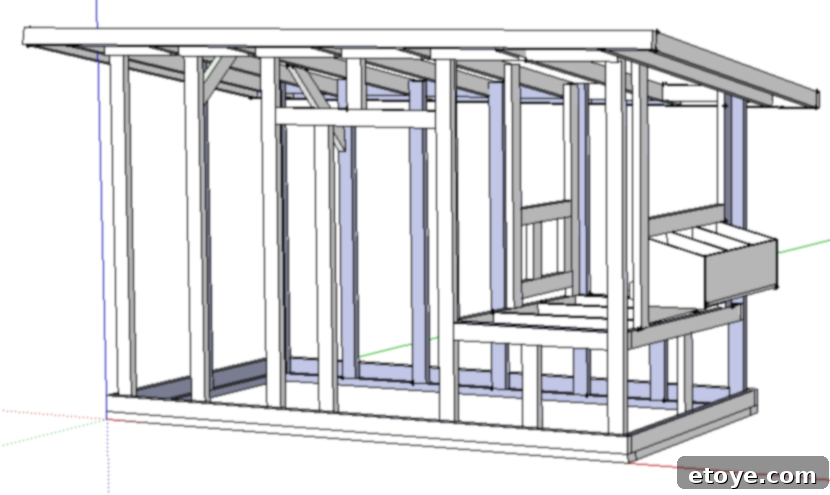

My search for free chicken coop plans online that met our specific requirements proved challenging. Consequently, I decided to leverage Google’s powerful 3D modeling software, SketchUp, to create a detailed working model of our coop. This tool was invaluable, allowing me to rotate the design from any angle, make precise adjustments, and visualize every component before construction began. While there was a learning curve, the time invested in mastering SketchUp paid immense dividends during the actual building phase. For those interested, I can provide two SketchUp files: one detailing the rough framing and another illustrating the finished framing with hardware cloth installed. These free chicken coop plans offer a solid foundation for your project.

For the free SketchUp files for the Palace Chicken Coop – RIGHT CLICK here for a zip file and select “Save link as” to download.

*** Special Note *** – When reviewing the SketchUp files, please be aware that all lumber dimensions are depicted as true 2 inch by 4 inch. In reality, standard dimensional lumber purchased from a mill is rough-cut to 2×4 and then planed down to a slightly smaller finished size, typically around 1.5″ x 3.25″. You will need to adjust the lengths of your 2x4s accordingly during construction to compensate for this difference.

To utilize these free SketchUp files, you must first download and install Google’s SketchUp program. This free software is available for download (ensure you select the correct version for your operating system, Mac or Windows). Please note that SketchUp is a sophisticated 3D application, and if you are not accustomed to such software, there can be a steep learning curve.

If you are not familiar with 3D applications or prefer a more traditional approach, we have invested in having our SketchUp files professionally converted into an exceptionally clear, user-friendly, and easy-to-read PDF format. These professional plans eliminate the need for 3D software and provide a step-by-step guide for your build. Access the comprehensive PDF plans here!

Key Design Features for Optimal Chicken Comfort and Care

Our DIY chicken coop, dubbed The Palace, was meticulously designed with specific features to ensure the comfort, safety, and health of our flock, while also prioritizing ease of maintenance for us. The final design incorporated:

- Capacity: Ample space designed for 5-7 standard-sized egg-laying hens.

- Run Space: A generous 10 square feet of run space per bird, providing plenty of room for foraging and exercise.

- Coop Space: A comfortable 3 square feet of enclosed coop space per bird, meeting recommended guidelines for happy hens.

- Roosting Space: At least 1 foot of roosting rail per bird, ensuring adequate and comfortable sleeping arrangements.

- Nesting Boxes: A ratio of 1 nesting box per 3 birds, promoting laying privacy and reducing competition.

- Sloped Floors: Both the main coop floor and nesting box floors are strategically sloped to facilitate water drainage during cleaning, contributing to superior hygiene.

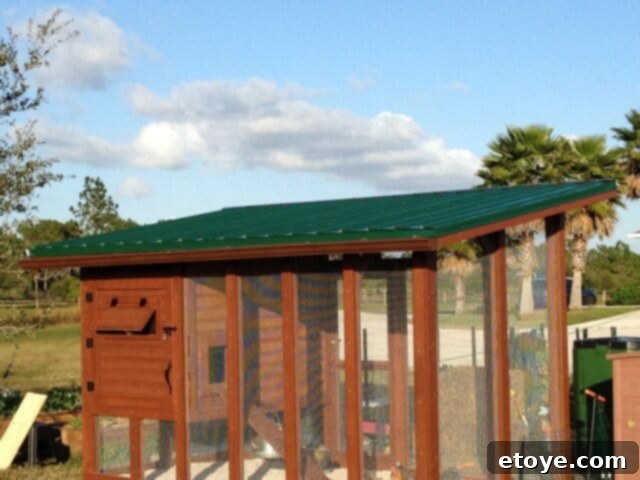

- Durable Roof: A sloped metal-over-wood roof not only adds structural stability but also serves a practical purpose for rainwater collection.

- Headroom: A minimum interior height of 6 feet, allowing an adult to stand comfortably inside for easy cleaning and maintenance.

- Robust Construction: Engineered for exceptional strength and durability, guaranteeing longevity and stability against the elements.

- Accessible Doors: Multiple easy-access doors for efficient cleaning, convenient egg harvesting, and seamless hen access.

- Elevated Foundation: A raised foundation specifically designed to prevent flooding, a critical feature for our environment.

- Predator Protection: All screened areas utilize durable 1/2″ hardware cloth, providing superior protection against predators.

The entire footprint of the structure measures 12 feet by 6 feet. The enclosed coop itself is a spacious 4 feet by 6 feet. The roof features a substantial 1-foot overhang on all sides, resulting in a total roof dimension of 14 feet by 8 feet, offering excellent protection from sun and rain. Furthermore, the coop floor is strategically elevated approximately 30 inches above the run floor, enhancing drainage and promoting a healthier environment for the hens.

Building the Foundation: A Secure Base for Your Chicken Coop

One of the primary challenges I anticipated for our DIY chicken coop project was managing the potential for flooding in the designated area. The previous summer had brought such heavy rainfall that the ground became completely saturated – a veritable sponge where every step caused water to well up around your boots. Although an existing concrete pad was present, we reserved it for a future garden shed or workspace. My solution was to pour a new footer, directly attached to the existing pad, which would elevate the entire chicken coop approximately 6 inches higher. This crucial elevation ensures ample room for drainage, even if the ground were to become fully waterlogged again.

Accuracy is paramount during this foundational step. I meticulously ensured that everything was perfectly square and level before proceeding. After carefully framing the footer, I incorporated rebar for added structural strength and laid drainage stones to actively facilitate water flow away from the chicken coop, further enhancing its flood resistance.

For mixing and pouring the concrete, I utilized a mixer rented from Home Depot. The footer, measuring 6 feet wide by 12 feet long and 6 inches deep, equated to 24 linear feet and required over half a ton of concrete. While a mixer is an option, for larger projects like this, I highly recommend calling a professional concrete company to deliver your required concrete pre-mixed. Your back will undoubtedly thank you for saving the strenuous labor!

Upon removing the forms after the concrete had set, I discovered an unexpected artistic touch embedded in the surface.

It appears Jaden, with innocent intentions, allowed the chickens to roam some time after the cement was poured but before it had sufficiently cured. I soon located the guilty party nearby, looking rather suspicious with her “concrete shoes.” To this day, she maintains her innocence, blaming it all on Chicken Little – a charming addition to the coop’s history!

To further enhance the drainage capabilities of our DIY chicken coop, I integrated a four-foot section of PVC pipe into the lowest part of the coop’s footprint before the concrete pour. This pipe was carefully cut, drilled with holes approximately 2 inches apart, and assembled to function as a crucial drain, ready to channel away any significant downpour or excess water.

Here is another perspective of the integrated drainage system, showcasing its thoughtful placement within the foundation.

To prepare the run floor, I ordered a half cubic yard of gravel and a full cubic yard of sand from a local aggregate company. They conveniently delivered it directly to my driveway, a far more economical solution than purchasing numerous heavy bags from a home improvement store, not to mention saving countless trips. The gravel was initially used to build up the base of the coop floor. This layer would later be covered with a weed prevention cloth, followed by the addition of sand. This multi-layered approach effectively raised the coop’s “floor” at least six inches higher than the surrounding ground, a strategic design choice to keep our ladies’ feet dry and the coop well-drained, especially during Florida’s rainy season.

Framing the Structure: Building the Bones of The Palace Chicken Coop

Undertaking the framing phase was a new experience for me. While I had a general conceptual understanding of structural assembly, my practical framing experience was nonexistent. I dedicated significant time to researching nailing requirements and the optimal methods for securely attaching the chicken coop to its robust concrete foundation. This research proved invaluable, providing a deep dive into fundamental framing principles. I printed out numerous images from my SketchUp model, using them as precise references for cutting each individual framing piece. Once cut, my family enthusiastically pitched in to help pre-stain all the lumber. We opted for a high-quality water sealant stain, ensuring thorough coverage on every piece, particularly those destined for direct contact with the concrete foundation, where moisture resistance is critical.

I was incredibly fortunate to have the helping hands of my family during the wood staining process, making a large task much more manageable and enjoyable.

The combined effort of cutting and staining all the lumber components consumed considerably more time than initially anticipated. Reflecting on the process, it might have been more efficient to paint or stain the assembled structure. This is certainly a point for future DIY chicken coop builders to consider!

The framing itself spanned several days. For those tackling a similar project solo, a crucial piece of advice is to make liberal use of clamps and temporary braces. These tools are indispensable for holding components precisely in place while you work, ensuring accuracy and stability throughout the build.

After successfully erecting the initial walls and roof beams, I utilized a powder-activated nailer to securely fasten the kick plates to the concrete foundation. I spaced fasteners approximately every foot, likely more than strictly necessary, but I thoroughly enjoyed operating the tool, and a few extra fasteners certainly don’t hurt. It was important to adjust the powder loads based on whether I was nailing into the pre-existing concrete pad or the newly poured footer.

From this opposing angle, the intentional tilt of the coop floor becomes more apparent, sloping gently towards the side where the main access door would later be installed. This design feature is critical for effective water drainage and ease of cleaning.

Next, I cut the coop floor from durable plywood and commenced the installation of the vital 1/2″ hardware cloth. This material is indispensable for creating a predator-proof barrier, securing the coop’s lower sections.

The process of installing the hardware cloth is quite straightforward: measure, cut, and secure. I used an automatic stapler to fasten the hardware cloth firmly to the framing. Later, this layer would be reinforced and protected by sandwiching it between the primary framing and additional finish framing pieces. An automatic staple gun is an absolute necessity for this phase of your DIY chicken coop build, significantly speeding up the process and ensuring a secure attachment.

Following the installation of the hardware cloth, I proceeded to install the finish framing pieces. These were specifically designed to not only hold the hardware cloth securely in place but also to provide a neat, finished edge to the interior of the coop.

These additional pieces play a critical role in firmly securing the hardware cloth to the interior of the coop, enhancing both its durability and its predator-proofing capabilities.

To provide immediate protection from the elements, I installed the roof sheathing at this stage. Some of the finish framing pieces were intentionally left off, to be added later after the main coop walls were in place, ensuring a cleaner and more integrated construction sequence.

The framing for the hen access door was carefully measured and constructed, ensuring a designated entry point for the chickens to move between the coop and the run.

Similarly, the nesting boxes were framed with precision. Each box measures approximately 14 inches across, 16 inches tall, and 12 inches deep, providing ample space for our hens. Crucially, the floor of each nesting box is tilted towards the coop interior, a design feature that allows water to drain effectively during cleaning, maintaining excellent hygiene. Notice the deliberate gap between the nesting box floor and the retaining board, further aiding in this drainage. This image also clearly illustrates the overall sloped main coop floor. It’s important to note that the nesting boxes are elevated approximately 6 inches off the main coop floor, a design choice to accommodate the Deep Litter Method effectively.

General Construction: Adding Practicality and Functionality to the Coop

For the interior surfaces of our DIY chicken coop, I opted for inexpensive vinyl flooring tiles from a local home improvement store. These tiles were incredibly quick and easy to install, and their smooth, non-porous surface promises to significantly simplify the cleaning process within the coop.

Here, you can see a picture of the removable stopper blocks. These blocks are a key element for effective cleaning, designed to be easily taken out when clearing the coop.

And with the stopper blocks removed, demonstrating how they facilitate the cleaning process by creating an unobstructed path for waste removal from the coop.

I then proceeded to build and mount the main access door, ensuring it was robust and provided easy entry for maintenance.

This is the opposite side of the main access door, showcasing its construction and how it integrates with the coop’s exterior.

Next, I constructed the crucial access ramp, providing a safe and easy path for the hens to enter and exit their coop. This ramp is a key component for the daily movement of the flock.

The ramp is ingeniously secured using four eye bolts, with the two at the bottom cleverly modified into hooks by cutting them with a hacksaw. This design allows the ramp to be easily removed for cleaning with a hose. While I installed this after the coop walls were up, I wanted to present it here to maintain the flow of construction steps.

Enclosing The Palace: Building the Coop Walls and Doors

The walls of our Palace Chicken Coop were constructed using very inexpensive vinyl siding sheets sourced from Lowe’s. These shiplap boards feature an overlapping edge, which simplifies installation and creates a clean, weather-resistant finish. My approach was to build each panel, install it onto the coop frame, trim as needed, and then stain the boards for durability and appearance. Most of the trim pieces used were 1 x 4 strips. I chose these strips over standard 1 x 4 boards primarily because they were significantly more affordable and already had a convenient rounded edge. Surprisingly, these strip boards also exhibited very few knots and were remarkably straight, making them an excellent choice for this DIY chicken coop project. During installation, I discovered that I needed to modify two of the finish framing pieces to accommodate the ventilation and siding above the main coop door. The roof’s overhang would have otherwise interfered with the door’s opening. Using a skill saw set to the appropriate depth, this modification was a straightforward fix.

Additionally, I secured a 2×4 to serve a dual purpose: acting as a robust door stop and providing crucial support for the siding panels. Ventilation holes, essential for airflow within the coop, were created using a 2″ hole saw and then covered with durable 1/2″ hardware cloth to keep predators out while allowing air circulation.

Next, I meticulously built and trimmed the main coop door, ensuring a snug fit and smooth operation within its frame.

Here’s a close-up view of the back of the coop door, clearly illustrating how the 1/2″ hardware cloth is securely sandwiched between the siding and the trim pieces. This construction method ensures maximum predator protection while maintaining a clean finish.

Once built, the door was carefully installed onto the chicken coop, integrating seamlessly into the overall structure.

The same precise process was then repeated for constructing and installing the siding on the remaining sides of the coop, ensuring consistency and a uniform finish.

Here, the back coop wall is fully installed, demonstrating the solid enclosure taking shape.

This image shows the side of the coop housing the nesting boxes, now enclosed and protected by the siding.

And here is the side wall where the chicken ramp provides access, completing the exterior enclosure.

Both the interior and exterior of the coop were stained for protection and aesthetic appeal. During this phase, Nathan found the new coop irresistible and decided to pretend he was a hen, thoroughly inspecting his new potential abode!

I then constructed the nesting box cover using leftover siding and trim pieces. An additional trim piece was attached to the wall to create an effective overhang, designed to minimize or eliminate any water leakage into the coop from the nesting boxes. I also plan to apply weather sealing around the rim to ensure it is completely watertight. While it might be subtle in this picture, there is also a protective lip at the bottom of the siding around the nesting boxes, further enhancing water resistance.

Finally, I installed the remaining finish framing pieces beneath the coop. This image provides an excellent view of the connection point between the pre-existing concrete pad and the newly poured footing. Utilizing the existing pad significantly reduced the overall concrete requirements for this DIY chicken coop project. The generous height of the coop also ensures adequate headroom for our hens, contributing to their comfort and our ease of access.

Preparing the Run Floor: Drainage and Comfort for Your Flock

To establish a clean and functional floor for the chicken coop run, I first laid down weed block cloth. This serves two vital purposes: it prevents undesirable weeds from growing up through the floor, and more importantly, it stops the layer of sand from washing down and mixing with the underlying rock base. Crucially, the weed block cloth is permeable, allowing water to effectively seep through into the integrated drainage system below, maintaining a dry and healthy environment for the chickens.

To help secure the weed block cloth in place and create a smooth transition, sand was carefully distributed around the edges of the run floor.

Then came the substantial task of moving this cubic yard of sand…

…into the coop run area. Ultimately, I estimate we achieved a base layer of slightly less than 6 inches of sand on top of the initial four-inch rock base. This multi-layered approach ensures excellent drainage and provides a comfortable, maintainable surface for our chickens, perfect for implementing the Deep Litter Method.

Roofing The Palace: Protecting Your Flock from the Elements

The next phase involved building and painting the gutter system. At fourteen feet in length, the gutter required multiple pieces to be assembled. While the assembly itself was fairly straightforward, it presented a perfect excuse to acquire a pop-rivet tool – a delightful addition to any DIY enthusiast’s collection! I always find great satisfaction in adding new tools to my workshop.

The gutter was then securely installed along the edge of the coop. I initially considered fabricating wedges to ensure the gutter was perfectly parallel with the ground. However, I ultimately decided that the slight 10-degree difference between the roof slope and the ground could be sufficiently accommodated during mounting. Upon installation, I realized the lower end of the gutter would sit below the drip edge of the roof. To rectify this, I cut a piece of aluminum from an unused section of gutter, painted it to match, and installed it so it overlapped the back of the gutter, positioned neatly beneath the roof’s drip edge. This minor adjustment ensured optimal water collection and prevented runoff.

Following the gutter installation, I carefully papered the roof deck, laying down a protective underlayment. Subsequently, 1×4 stripping was added, strategically spaced to provide a crucial breathing room between the sheathing and the upcoming metal roof panels. This air gap is vital for ventilation and preventing moisture buildup.

Taking a helpful suggestion from this guide on installing metal roofs, I laid the metal roofing panels out on the lawn to precisely determine the placement of the ribs in relation to the roof’s edge. This pre-planning allowed me to trim both side edges of the roof panels as needed, ensuring that no rib would interfere with the intended placement of the roof edging, resulting in a cleaner and more professional finish for our DIY chicken coop.

Finally, the robust metal roofing was installed onto the coop. If you’ve never undertaken any type of roofing installation before, it’s wise to allocate extra time for this particular step. Always prioritize safety; metal sheets are large and unwieldy, and their edges can be extremely sharp. Be mindful of wind conditions, as large panels can be dangerous to handle. Secure attachment and careful handling are key to a successful and safe metal roof installation for your chicken coop.

The Finishing Touches: Completing Your Palace Chicken Coop

The final stretch of building the Palace Chicken Coop involved refining the interior elements, specifically the nesting boxes and the crucial roost bar. Our chickens had seemed quite content with the temporary roosting bar I initially provided, so I simply rounded its edges slightly and chose to leave it unstained. There wasn’t a specific technical reason for this, beyond a personal preference for its natural look. I also speculated that the unstained wood might be easier for the chickens to perceive, as they seemed to struggle with accurately judging a stained roost I had previously installed during periods of low light.

I utilized some trim pieces to give the nesting boxes a more snug and cozy feel. While I’m fairly certain the hens themselves were indifferent to these aesthetic enhancements, I personally appreciated the finished appearance the trim provided.

Here’s an exterior view of the nesting boxes, clearly showing the installed trim pieces. My wife and children thoughtfully added a few fake wooden eggs to the boxes, providing a gentle hint to our girls about their intended purpose and location for laying.

I then built and installed the main coop door, designed with a simple yet effective rope and pulley system. The rope, easily accessible from the front of the coop, allows the door to be effortlessly opened and secured in the open position with a cleat. We typically leave the door open, closing it only during particularly windy or cold nights to ensure our hens’ comfort and safety. To ensure smooth operation within its track, I ingeniously added furniture slides to the door, allowing it to glide with minimal friction.

A closer inspection of the door reveals a key predator-proofing feature: when closed, the door extends slightly below the main opening. This design, in theory, helps deter clever raccoon fingers or other small predators from prying the door open.

This image showcases the cleat, strategically placed for securely holding the coop door in its open position.

For added convenience, we hung a small child’s rake on the exterior of the coop. This simple tool proves incredibly handy for turning over poop and spreading fresh wood chips within the coop, making routine cleaning much easier!

Once everything was complete, we gently moved our girls into their magnificent new home, The Palace Chicken Coop. They appear to be very happy and settled in!

You can read all about our exciting “first egg-perience” here: Our First Egg. And for a delicious culinary adventure, here’s one of the recipes my wife crafted using our fresh eggs: Crepes with Salted Lemon Butter Caramel.

Valuable Lessons Learned from Building a DIY Chicken Coop

Embarking on a large DIY project like building a chicken coop inevitably comes with a learning curve. Here are some of the key insights and lessons we gained during the construction of the Palace Chicken Coop, which we hope will benefit your own building endeavors:

- Verify Lumber Lengths Diligently: Always double-check the actual length of your lumber, especially longer pieces. We found that the 12-foot and 14-foot boards we purchased were nearly two inches longer than specified. Failing to catch this discrepancy early on would have meant the coop would not have fit correctly on our prepared footer, causing significant rework.

- Master Foundation Squaring Techniques: When squaring your footer or any rectangular foundation, consistently employ reliable methods such as the 3-4-5 triangle method or the diagonal corner method. Both techniques assume that opposite sides of your rectangle are equal in length, which is fundamental for achieving a perfectly square structure.

- Embrace Assistance or Strategic Clamping: Having an extra pair of hands during framing makes a monumental difference, making it much easier to hold large pieces precisely in place. If you’re tackling the project solo, do not hesitate to make generous use of clamps and temporary alignment guides. These tools are your best friends for maintaining accuracy and stability.

- Optimize Chicken Coop Ramp Rung Spacing: The rungs on our chicken coop ramp were constructed from 1x2s spaced on 6-inch centers. We observed that our hens sometimes seemed to “skate” or slip between these rungs. A slightly closer spacing might have been more ideal. While they quickly adapted and navigate the coop frequently, it’s something to monitor. If you’re introducing smaller or younger chickens, consider building a ramp with closer-spaced rungs initially, and you can always swap it out for a wider-spaced version as they mature.

- Integrate a Removable Shavings Board: We added a highly practical, removable board across the bottom of the coop door opening. This simple addition prevents shavings and bedding material from spilling out when the door is opened. It’s held in place by 1×2 strips on each side of the coop frame and slides upwards for easy removal during cleaning.

- Thoroughly Research Material Orders: Never assume that a big-box home supply store employee possesses comprehensive knowledge for complex orders. When ordering materials for our 8 x 14-foot metal roof, I sought assistance from their special projects desk. After picking up all the parts, I consulted the manufacturer’s website for installation instructions and quickly realized I was missing half the components required to complete the roof as I had initially explained it. It is far better to invest time in thorough personal research to determine exactly what you need before visiting the store, rather than facing a two-week delay waiting for missing parts to be delivered.

- Pre-Drill for Efficiency and Safety: Pre-drilling holes for nails and screws, especially when working at height on a ladder, makes the assembly process significantly easier, reduces the chance of wood splitting, and enhances safety.

- Consider Nesting Box Access for Children: If you have young children eager to collect eggs, as we do, top-opening nesting boxes might not be the most convenient design. We had to place a step stool beside the coop to allow our kids to reach and open the boxes. While I wouldn’t lower the boxes (to accommodate the Deep Litter Method), I might consider a back-access door design in future builds to simplify egg collection for little ones. Just a thought!

- Account for Sloping Floors in Design: We love the slanting floors in both our nesting boxes and the main coop for drainage. However, it is crucial to meticulously factor this slope into your wall construction. Double-check all your measurements and calculations. Installing sloped walls is also another excellent opportunity to enlist some assistance, ensuring accuracy and ease of installation.

Overall, we are incredibly pleased with the progress and the functionality of our Palace Chicken Coop so far. We will continue to share updates as our flock thrives in their new home.

See What Others Have Built from Our Chicken Coop Plans!

Are you looking for inspiration or to see the versatility of our Palace Chicken Coop plans in action? Check out these amazing coops built by our satisfied customers! I am consistently blown away by the creativity and ingenuity with which people have adapted these robust chicken coop plans into their own unique works of art. Click the photo below for a quick tour and marvel at the diverse variations!

Ready to Build Your Own Palace Chicken Coop? Get Our Professional PDF Plans!

We are incredibly excited to announce the release of our professionally converted 3D SketchUp plans into a highly detailed and user-friendly 32-page PDF document. These comprehensive construction plans are designed to guide you effortlessly through the process of recreating this magnificent chicken coop for your own backyard. Frankly, I wish I had these detailed plans when I embarked on my original build; the process would have been significantly smoother and faster!

The premium PDF plan set includes:

- 32-Page Comprehensive PDF: Featuring over 100 meticulously detailed drawings and illustrations, leaving no stone unturned in your construction journey.

- Complete Bill of Materials (BOM): A full list of all necessary materials, complete with estimated costs to help you budget effectively.

- Editable Bill of Materials Spreadsheet: A convenient spreadsheet format to easily track your actual expenses as you purchase materials.

- Revamped 3D Model: An updated and enhanced 3D model, perfect for visualizing the finished coop and sharing your vision with family or significant others.

To give you a glimpse into the quality and level of detail within these plans, here is a sample page. You’ll see just how thoroughly each step and component is illustrated, making your DIY chicken coop project a breeze.

We are exceptionally proud of how these construction plans have turned out and genuinely hope they become an invaluable resource for every aspiring chicken coop builder. These plans will undoubtedly pay for themselves many times over, simply by saving you countless hours of design, measurement, and troubleshooting. I personally spent extensive time creating the original 3D model and even more hours painstakingly extracting measurements for cutting pieces in the workshop. This comprehensive set of plans eliminates that arduous process for you, allowing you to focus on the joy of building.

The link below will direct you to our trusted partners at Happy For A Living, where you can securely complete your purchase. Simply fill out your information, and you will gain instant access to all the files for the Palace Chicken Coop plans, ready for download!

BUY THE STEAMY KITCHEN PALACE CHICKEN COOP PLANS NOW!

Thank you for your invaluable support in our shared passion for happy, healthy chickens!

Of course, for those who prefer to work directly with 3D modeling software, the original SketchUp files remain available free of charge.

Free Chicken Coop Plan: Download the Original Google SketchUp Files

To access and utilize these free chicken coop plans in SketchUp format, you must first download and install Google’s SketchUp program. This free software is available for download (ensure you select the correct file for your operating system, Mac or Windows). Please be aware, however, that SketchUp is a powerful 3D modeling application and can be quite complex to use if you are unfamiliar with such software.

For the free SketchUp plans – RIGHT CLICK here for a zip file and select “Save link as” to download.